24 de febrero 954, Col. San Ramón,

C.P. 25020, Saltillo, Coahuila

Interested in our services?

BATIZ CONTROL INC®

Mexican company with more than 12 years of experience in the market, serving the industry by developing solutions to satisfy the needs of our clients and creating business relationships; always seeking to exceed the expectations of those who trust us and be part of their production strategies.

Today, our metalworking and powder painting processes have become a great alternative for those who take care of quality, delivery, cost and service in their subprocesses and maquila.

Today, our metalworking and powder painting processes have become a great alternative for those who take care of quality, delivery, cost and service in their subprocesses and maquila.

Our main services:

- Manufacturing of serial parts

- Laser cutting

- Shot blasting /shotblasting

- Powder coat /Electrostatic paint

- Design and execution of turnkey projects

- Development of POKA YOKES

- Check IN FIXTURES development

- Construction of conveyor belts

- Installation of safety curtains

SINCE 2011

+ 160

Executed projects

For 14 years,

BATIZ CONTROL INC® has helped clients optimize their production process, increase efficiency and improve their results with the highest standards of quality and service.

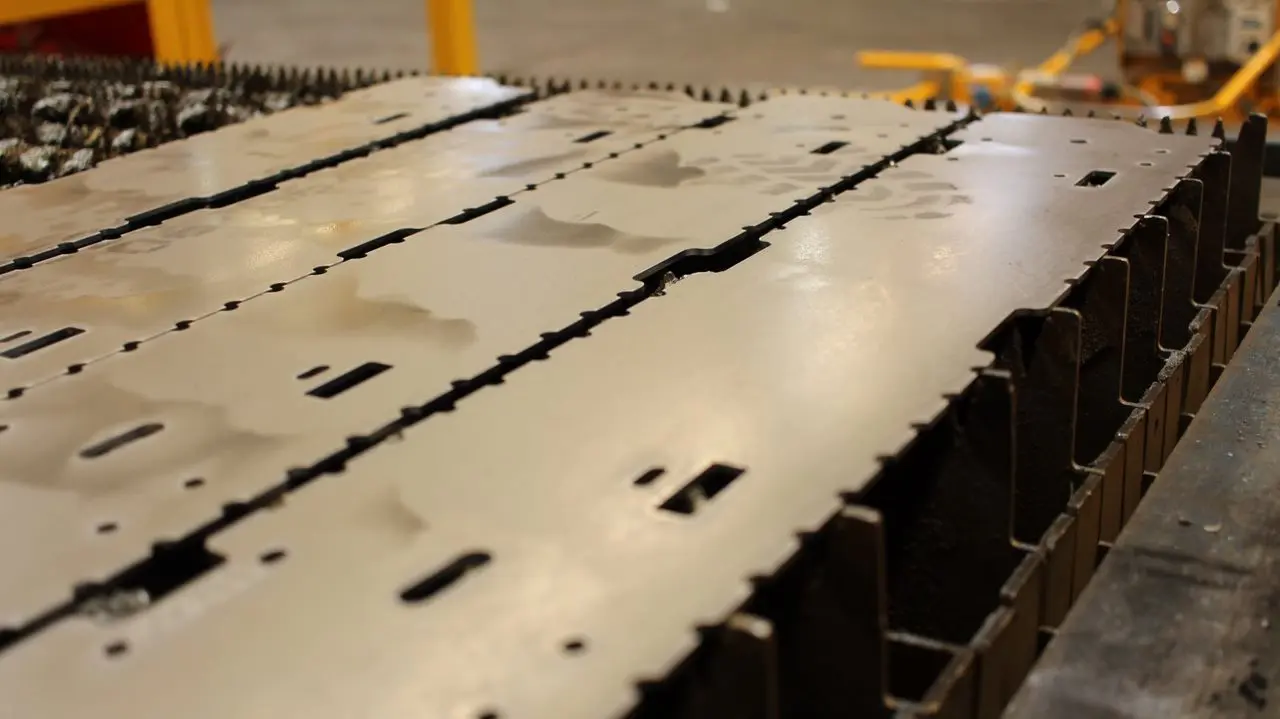

LASER CUT

The Laser Cutting process is the number one option for the metal parts cutting machine in terms of precision, edge quality, speed and profitability. The laser cutting service offers perfect cutting, even on the hardest of steels. Complex contours, small holes and narrow bands are cut cleanly and without burrs

READ MOREQuote now:

+52 844-271-70-88

+ 500,000

Cut Parts

Manufacturing specialist

Our comprehensive approach ranges from design to implementation, and one of our strengths is manufacturing. We have state-of-the-art facilities including laser cutting, shot blasting and electrostatic painting services.

CURRICULUM BCI

- 2 buildings with more than 20,000 square feet

- 4 forklifts of 4, 5 and 8 tons

- 2 cranes for the electrostatic painting area

- Loading spring and area to receive material

- Shotblasting cabin 8ft x 40ft

- 2 painting booths

- 2 convection ovens of 8ft x 30ft

- 100 ton bending machine

- 2 trueLaser brand laser machines:

3030 5ft x 10ft (4,000 watts)

1040 6ft x 13ft (6.00o watts) - 9 welding stations

- TruArc automated welding machine

- QMS development for certification under ISO 9001:2015 Standard

We generate and develop projects for the industry in general with the highest levels of service, efficiency and quality, always seeking, achieving and preserving, above all, the physical integrity of the people who operate the automation equipment.

CEO

Juan Carlos Villanueva

Juan Carlos Villanueva

SHOTBLASTING

Our shot blasting cleaning service, also known as shotblasting, is a highly effective and versatile surface cleaning and preparation process. By using abrasive particles projected at high speed onto the surface, we effectively remove rust, corrosion, old paint and other impurities, leaving the surface ready to be treated or coated.

READ MOREQuote now:

+52 844-271-70-88

+ 700,000

Treated parts

TRANSFORMATION CENTER

At our center, we merge exceptional customer service, the expertise of our highly trained technicians and the expertise of our engineering team with cutting-edge technology in cutting, painting, welding, bending and engraving. This allows us to provide our customers with the opportunity to carry out large-scale production projects, creating high-quality parts and assemblies. We bring all of these processes together to deliver products that inspire strong consumer confidence.

ELECTROSTATIC PAINT

Our powder coating service, also known as electrostatic painting, is an advanced finishing technique that offers durability, strength and a flawless look to a variety of parts and surfaces. This process uses fine pigment powder particles that electrostatically adhere to the surface through an electrically charged process.

READ MOREQuote now:

+52 844-271-70-88

+10M

Painted pieces

OUR EXPERIENCE SUPPORTS US

WHY CHOOSE US?

At Batiz Control Inc we are committed to meeting our customers' requirements by delivering high quality products and services that exceed our customers' expectations. We strive to continually improve our performance and capabilities to maintain our competitive advantage.

- Design

- Machining

- Integration

- Programming

- Turnkey projects

- Press design

- POKA YOKES development

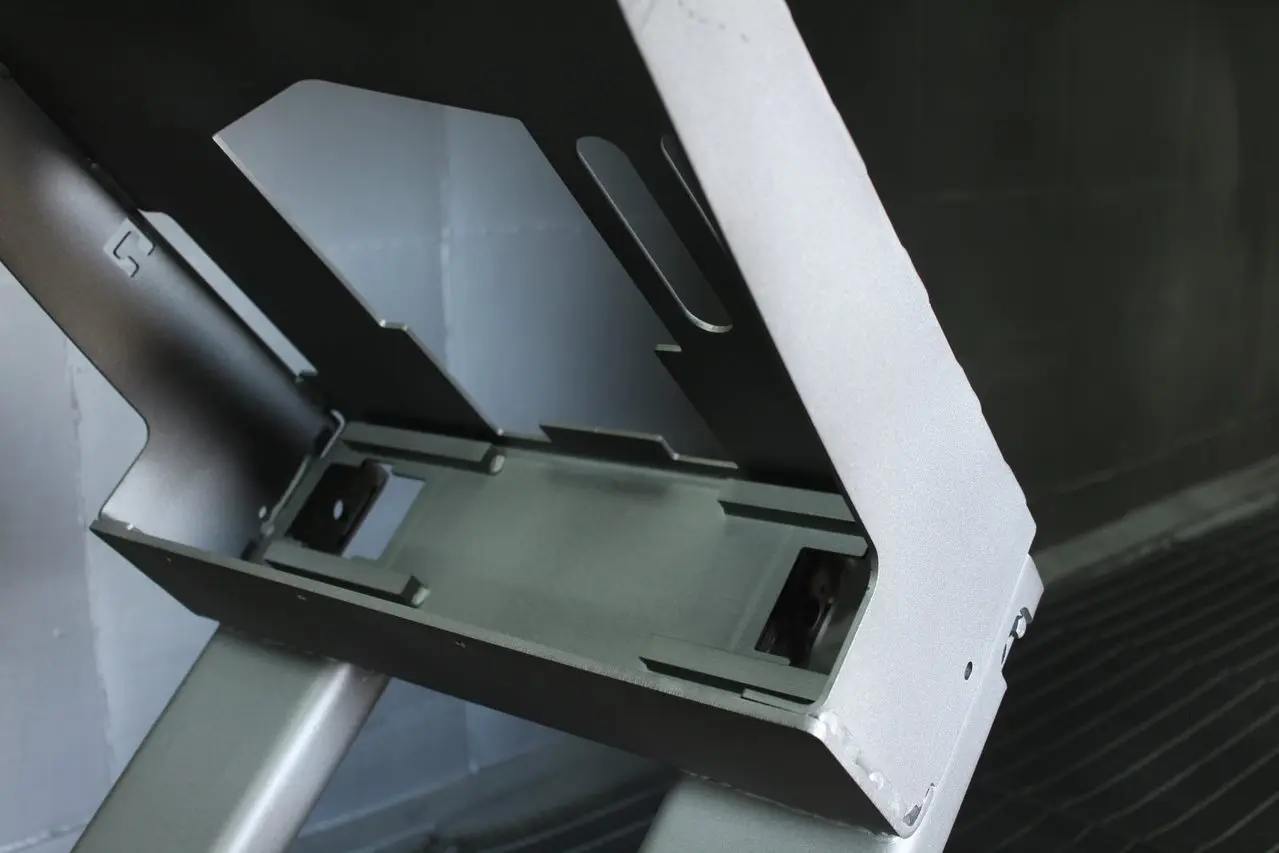

- Development of CHECK IN FIXTURES

- Construction of conveyor belts /Conveyors

Control equipment such as:

- Drivers

- Encoders

- IPC-PC Industrial

- ICB - Control cards

- Laser cutting

- Punching

- Tube rolling

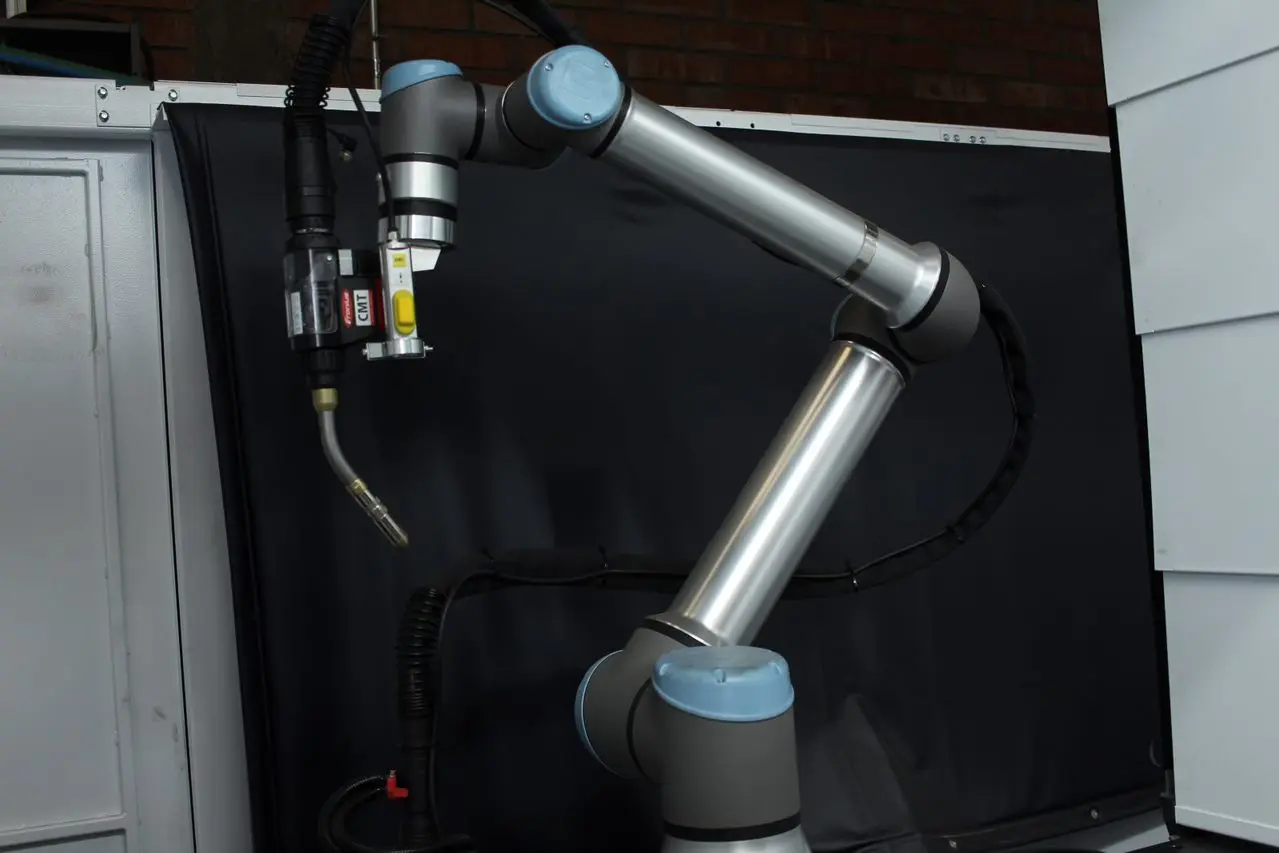

- Robot welding

- Bending Machine

- Land measurement

- Land installation

- Various electromechanical works

- Industrial installation of electrical wiring

- Shot blasting /Shotblasting

- Oven up to 250° Centigrade

- Powder coat /Electrostatic paint

- Painting service for industrial structures

15 YEARS FORMING ALLIANCES

OUR CLIENTS

ANY QUESTIONS?

WE ARE HERE TO HELP YOU

For faster attention, you can use the chat below

left to contact one of our specialists