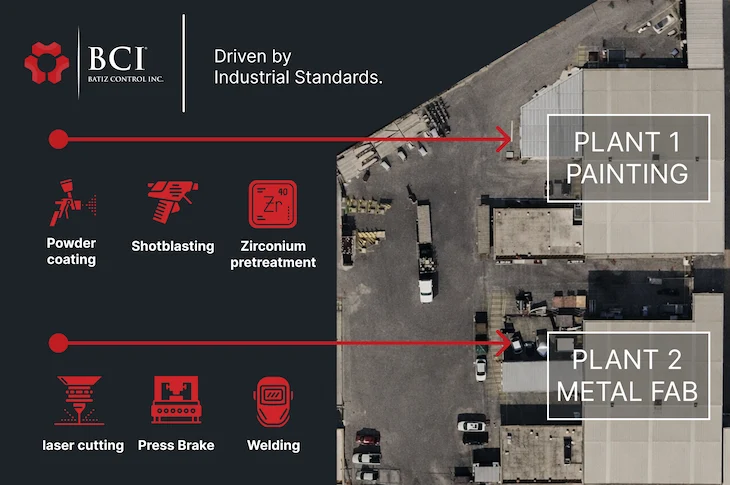

Our plant is divided into two specialized facilities, designed to comprehensively cover the manufacturing, finishing and logistics processes.

We specialize in low-volume metal components and welded structures for OEM industrial applications, supporting production, launches and engineering-driven requirements.