We develop complex industrial projects with demanding technical requirements, integrating engineering, manufacturing, and automation to solve critical challenges with precision, efficiency, and reliability.

We are ISO 9001:2015 certified, supporting standardized processes, quality control, continuous improvement, and consistent compliance across every industrial project we execute.

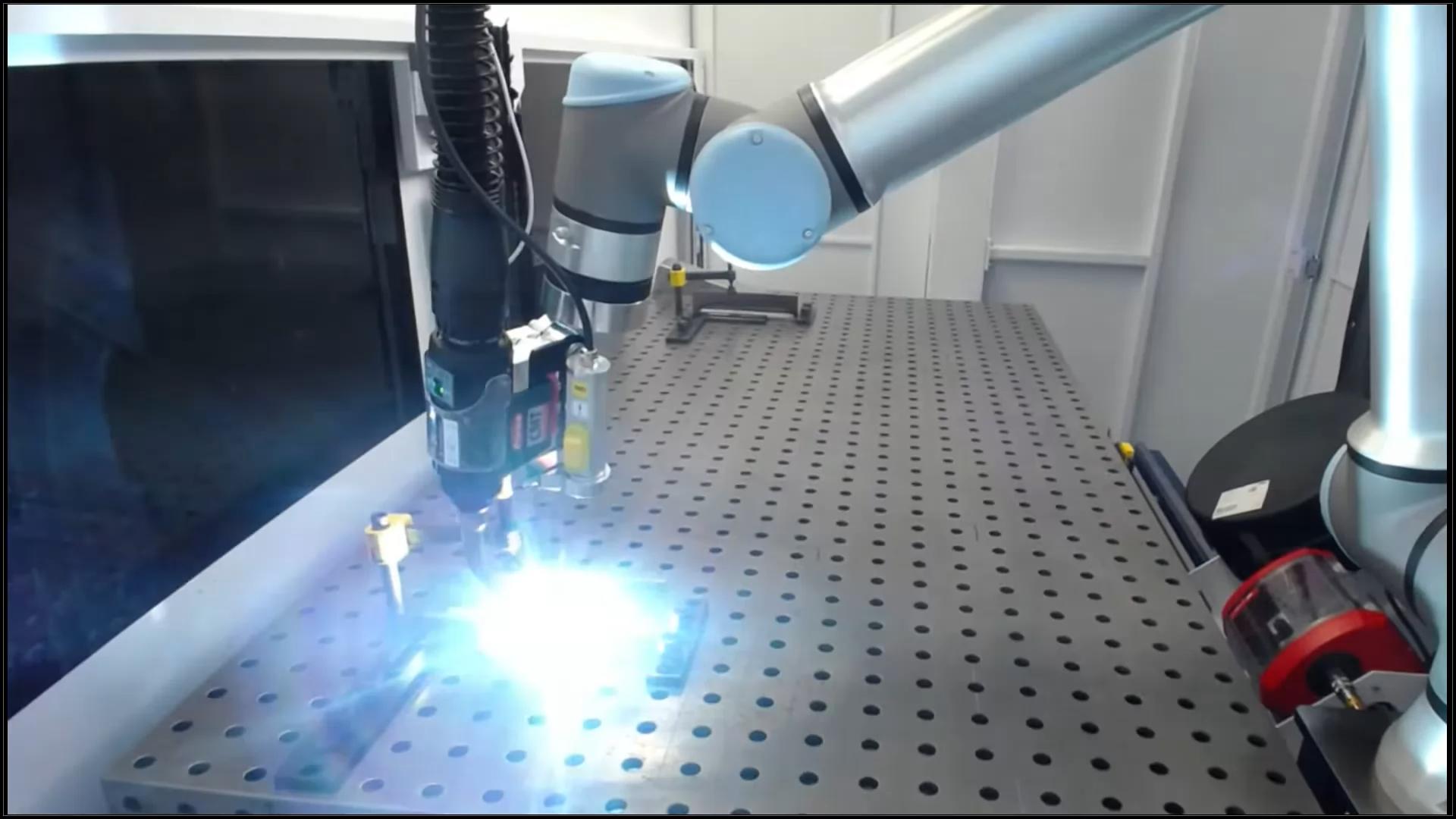

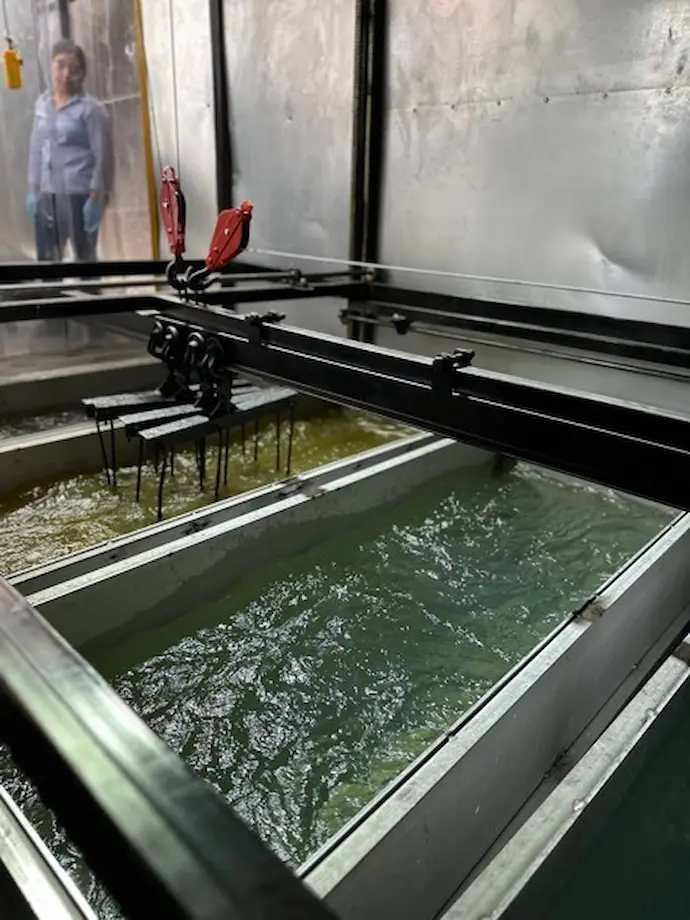

We operate specialized equipment and manufacturing infrastructure for precision metal fabrication, enabling tight tolerance control, shorter lead times, and scalable production capacity.

Located within the USMCA corridor, near the main industrial parks in Saltillo and the surrounding region, we simplify logistics, ensure rapid response times, and remain closely connected to key supply chains.