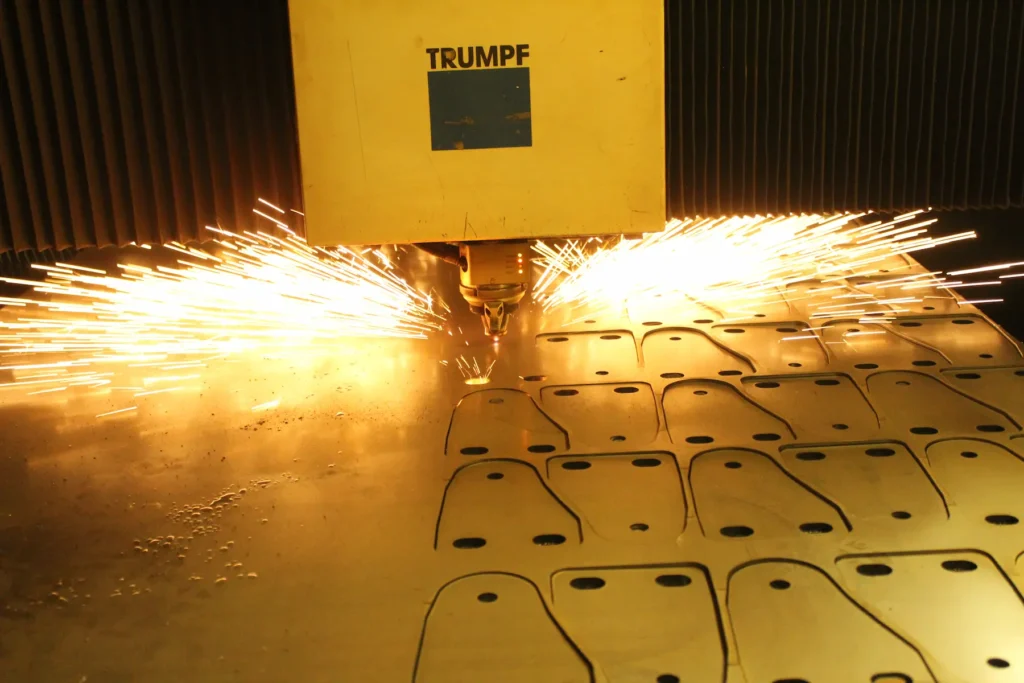

In an increasingly demanding industrial environment, metal fabrication manufacturing can no longer be approached as isolated processes. Today, companies require suppliers with vertical integration capable of controlling every stage of fabrication to ensure quality, compliance, and operational efficiency. For procurement directors and plant managers, selecting a strategic partner in Mexico means reducing risk, ensuring traceability, […]